Deactivation/Decontamination

One of the biggest challenges in working with HDs is how to successfully remove them from the environment. Based on wipe test studies, it is known that HDs can remain on surfaces for extended periods of time (Connor, Anderson, Sessink, & Spivey, 2002; Hansel et

al., 1997). They are also typically difficult to remove, based on chemical structure and diluent (Anderson, Connor, Power, & Dorr, 2001; Gonzalez & Massoomi, 2010).

Definitions

There is also confusion surrounding the terminology. Deactivation renders the HD inactive or inert. Decontamination physically removes the HD from the surface. From a practical standpoint, ensuring the hazard is no longer in the environment is the primary goal. Within this context, USP <800> is primarily geared toward the pharmacy environment, and has particular wording for biologic safety cabinets and other primary engineering controls where HDs are compounded. But for nurses, we are usually concerned with what's in our working environment and how to get rid of it. USP <800> also specifically lists "oxidizers" (e.g., peroxide or bleach products) for deactivation; unfortunately there is very little available information on which peroxide products can deactivate -- or decontaminate.

Products

Nurses may be tempted to use alcohol wipes or disinfecting wipes after a spill, as they are readily available where medications are administered. However, they are not effective for deactivation. Certain HDs can be deactivated by a 5.25% concentration of bleach (Benvenuto et al., 1993; Castegnaro et al., 1997; Roberts et al., 2006). Unfortunately, this concentration, which is similar to laundry bleach, is impossible to use in healthcare environments in liquid form. At this concentration, sodium hypochlorite is highly corrosive and generates dangerous fumes. This is part of the deactivation dilemma. Lower concentrations of sodium hypochlorite are also effective, but the efficacy decreases and the time required for deactivation increases. A 2019 review by Simon et a al concluded that sodium hypochlorite was overall the most efficient, although there is also more data on this agent than any other.

There are products on the market that can be helpful for deactivation. The oldest product is Surface Safe, which consists of a two packet set. The first packet contains a wipe saturated with 2% sodium hypochlorite and detergent; the 2nd packet contains sodium thiosulfate and alcohol, which helps neutralize the corrosive properties of the sodium hypochlorite while also enhancing the efficacy of sodium hypochlorite for some drugs. Their website now lists 8 drugs that can be neutralized [updated 6.23.19] although original packaging information listed approximately 20 HDs.

Pharma-Surface Guard is another 2-wipe product that is similar to Surface Safe, containing detergent and 2% sodium hypochlorite in the first packet and thiosulfate/alcohol in the second. The company website does not list the drugs that can be neutralized by this product.

.jpg)

Wipedown 1-2-3 contains 3 packets. The first uses 5.25% sodium hypochlorite, the second contains 2% sodium thiosulfate, and the third contains 70% alcohol. While this product has the most effective concentration of sodium hypochlorite, the inclusion of the separate alcohol pad is not needed for spills encountered by nurses outside of the compounding area. While PDFs are on their website, you must have a login to view them. The company website does not list the drugs that can be neutralized by the product.

Clorox Healthcare Bleach Germicidal Wipes, and Hydrogen Peroxide Cleaner Disinfectant Wipes are commonly used in healthcare settings as a disinfectants. Clorox now has a USP <800> information sheet although it is not easy to locate on their website. The sheet has efficacy data for both products tested against 5 marker HDs. The company also lists a 5-step protocol.

Decontamination

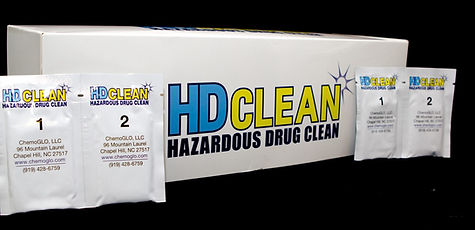

Designed for decontamination, HD Clean can help remove hazardous drugs from surfaces. Unlike the above products, it does not contain sodium hypochlorite and is therefore not corrosive and is devoid of the identifiable bleach odor. Their website lists 5 HDs that can be effectively removed with the wipes.

.jpg)

.jpg)

Ready to use packets are convenient but are designed for use in pharmacies where biologic safety cabinets used for compounding have a relatively small surface area (~10-12 square feet). For daily Infusion Department decontamination, or for spills occurring at the bedside where the affected area could be significantly larger since spills on floors tend to run in rivulets depending on how level the floor is and how well it is waxed, packets are impractical. A 10 foot by 10 foot spill would require multiple wipes and a great deal of time, labor and cost.

Peroxide based oxidizers have the potential for decontaminating.

Oxivir

One product, which is available as either a 11x12" wipe or in a liquid form, is Oxivir TB. In December, 2019, Diversey provided updated wipe test information from an independent laboratory showing no detectable HD residue was found after using their product. In addition, the product appears to be compatible with a number of common plastics, which theoretically could make it useful for removing trace HD from IV pumps. I will be reporting more on this product in the coming months.

As a follow-up to to our published study on bathroom contamination, we re-tested the patient bathroom. Two changes in practice were made which included use of a disposable flat mop for each bathroom, and changing to Oxivir. Results of this follow-up are not yet published, but after 4 days of testing, no drug residue was found. Additional research is warranted to evaluate the product in a more controlled setting.

Peridox

Another product commonly used before and after compounding is PeridoxRTU which is classified as a sporicidal agent. While not as noxious as sodium hypochlorite, it does have a strong acetic acid (vinegar) odor. The company has a list of the 6 HDs that are removed, which can be found here. It is safe for a variety of surfaces, although this list has not been harmonized with the leading pump manufacturers.

Summary

The deactivating packets are the best option for many but not all spills as we do not know what toxic reactions could occur with drugs that have yet to be tested. Failure to disclose on their websites the list of agents in which they are effective is unfortunate in that it leaves too many unanswered questions and could lead to a false sense of security.

The packets are also not practical for routine deactivation. Some have suggested using a spray bottle of bleach to wipe down areas. This is not recommended for spills as it can lead to increased contamination, and the generated bleach vapors would be problematic. And again, a 5% bleach concentration would be harmful for many surfaces in an infusion department. Peridox RTU may be the best alternative for routine wiping although there is little reported information on long-term effects on surfaces outside of stainless steel used for compounding.

While it makes sense to wipe our departments down at the end of the day with something, the ideal product does not yet exist, leaving the door open for more research and development.